No-bake System

-

Sand Mixing

-

Sand Reclamation

-

Mould Handling

-

Core Making

-

Coating Plants

-

Foundry Accessories

-

Omega Connect

-

Omega Spares

-

Omega Support

Sand Mixing

A full range of primary, secondary and thermal reclamation plants ranging up to 30 TPH

-

Omega Gamma Vator

-

Omega Low Level Sand Reclamation

-

Omega High Level Range Sand Machine

-

Omega GM Combination Shakeout and Reclamation

-

Omega GM Combination Shakeout and Reclamation Plus

-

Omega Shakeout Decks

-

Omega Cooler Classifier

-

Omega Sand Conveying Pressure Vessels

-

Omega Chromite Separation

-

Omega USR Secondary Attrition

-

Omega Thermal Reclamation

Sand Reclamation

Omega Sinto has a full range of semi-automatic mechanised mould handling systems. Choose from carousel, fast loop or shuttle designs to suit the range of mould sizes produced.

Mould handling is a crucial part of any foundry and Omega Sinto specialises in developing tailored solutions from fast loop to carousel systems with ancillary equipment such as flood coating, compaction tables, coring areas, automatic mould closing and pouring and cooling lines. Our mould handling equipment is suitable for any foundry as our engineers make efficient use of space and liaise directly with you to create a system that works.

-

Foundry Carousel Machine

-

Omega Fast Loop

-

Omega Shuttle

-

Omega Compaction Tables

-

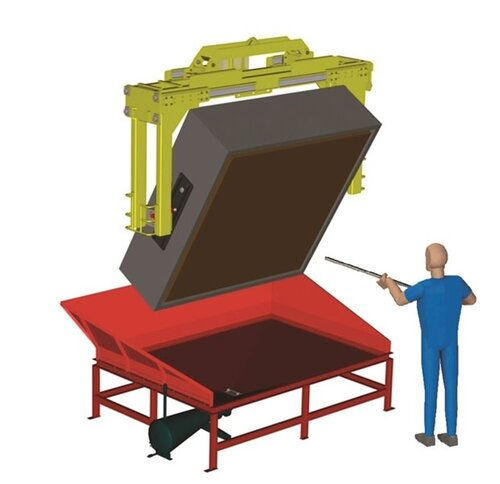

Omega Rollover Stripping Station

-

Omega Mould Drying

-

Omega Flood Coater

-

Manipulator Equipment

-

Omega Chain Manipulator

-

Automatic Mould Closing

-

Pouring and Cooling Lines

Mould Handling

We have a wide variety of ‘jobbing’ type core shooters to suit your core production needs.

Omega Sinto can offer core making equipment to suit every type of gas-hardened system.

At Omega, we have developed a range of core making equipment to suit the needs of any foundry. Each unit can be fully customised by our engineers to help meet specific requirements such as capacity or overall size. We understand that every foundry is different and therefore we work closely with each of our customers to produce the best machinery for optimising all core-making processes.

-

Omega Cold Box Core Machines

-

Basic Core Shooter Range

-

No Bake Core Shooters

-

Omega Core Shooter Machine

Core Making

Coating plants play an important part in any foundry. It’s important that sand is coated evenly and efficiently for optimum performance in the casting process. At Omega Sinto, we have developed a range of coating plant machinery to supply foundries around the globe. We manufacture automatic coating plants for the production of resin coated sand (croning sand) and oil/gas exploration FRAC sand. Including a disintegrator, coating mixer, cooler classifier and state-of-the-art control panel, our coating plant is the best solution to effectively coat sand.

Coating Plants